REMANUFACTURING

In beginning of 2013 Factory of rolling bearings and cardan shafts “FKL” have developed technology for large size bearings remanufacturing. For that process FKL has adequate equipment, special formed line and internal standards for realization of this activity.

Reparation process of bearings consists of following activities:

- Degreasing and rust removal

- Detailed control and detection of bearing defects

- Creating necessary constructional and technological documentation for remanufacturing for each bearing

- Grinding and honing of the raceway of inner and outer rings, cleaning, reparation or manufacturing a new cages

- Marking and installation of new rolling elements

- Bearings mounting

- Control of all requested parameters

- Appropriate protection and packaging

Main objectives of remanufacturing

Support the Customers to purchase a large size bearings in a way to avoid a high maintenance costs during the period of bearings exploitation.

Reduce the time of bearings replacement: Lead time to purchase a large size bearings usually takes up to 12 months . The remanufacturing in FKL factory takes up to 2 months.

Old equipment repairing problem solving. The equipment is usually so old and the customer finds impossible to purchase in the market the bearings with adequate dimensions. The reparation of the current bearings will solve the problem.

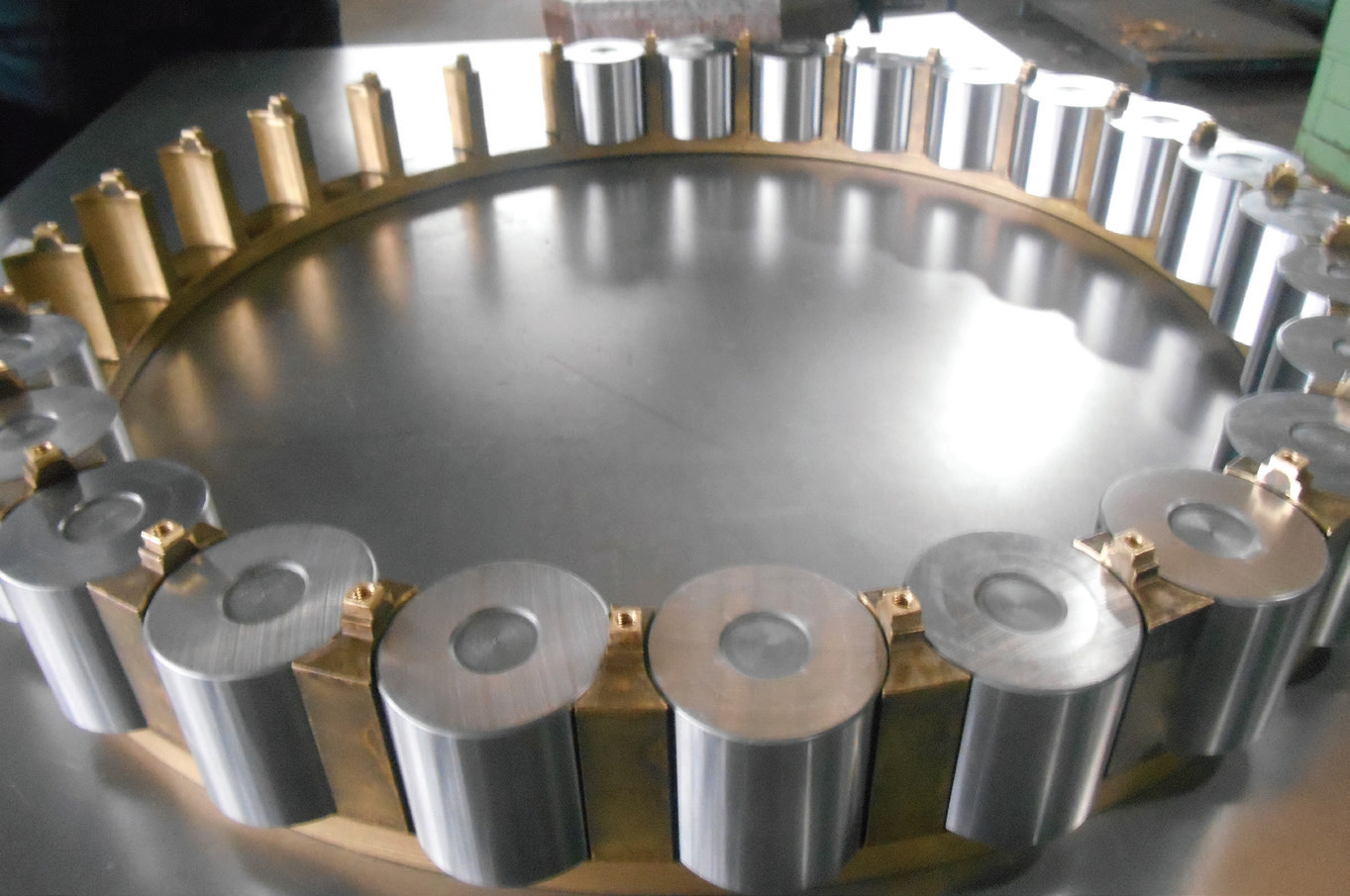

Remanufacturing is recommendable only for a large size ball, roller and spherical bearings.

Remanufactured bearings achieve equal life time and working performances as the new ones.

The main idea of reparation technology is caused by the fact that the one of the following components will surely wear out: outer ring, inner ring or rolling element . The components have to be reworked and the other components need to be grinded and polished. Other components will be adjusted in accordance to the dimensions decreasing of repaired components. In rare cases it could happen to replace two components at the same time.

Reparation of bearings is performed in same plant where production process of standard FKL program takes a place. FKL gives 1 year guarantee for remanufactured bearings as well as for the new bearings.

Factory FKL is able to repair ball, roller and spherical bearings with outer diameter from 300 up to 1000 mm. The price of repair depends on condition of bearings and its damage.