Factory of Rolling Bearings

Providing the Best Solutions

Years of Success

Experience in Bearing

Production

Premium Quality

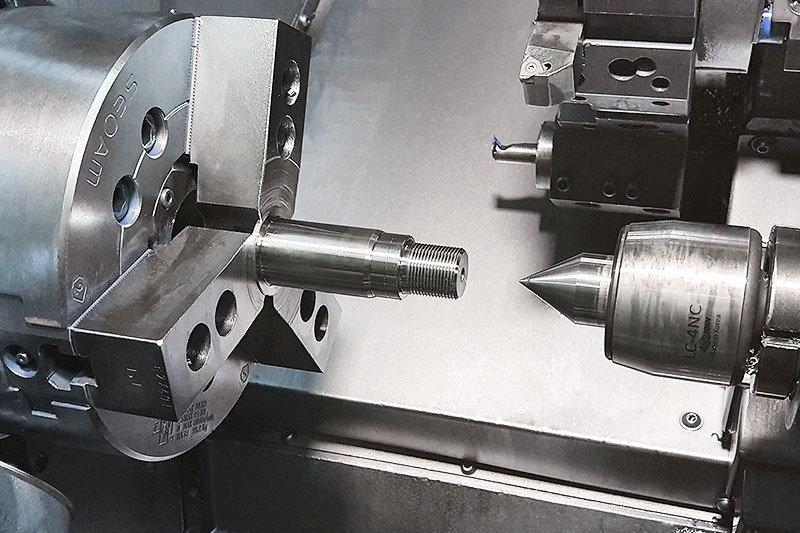

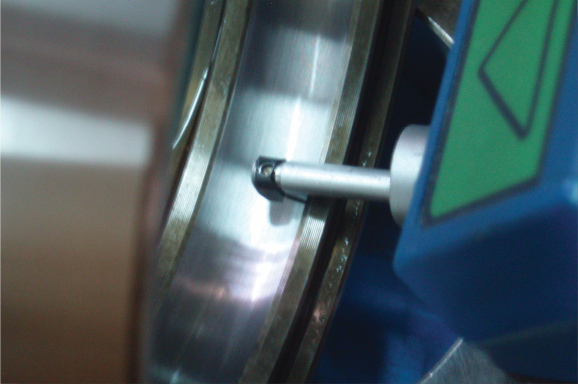

Complete manufacturing cycle

under 100% control

Customer Oriented

Customer Tailored

Solutions

European Origin

100% European

Products

PRODUCTS

PRODUCTION PROGRAM

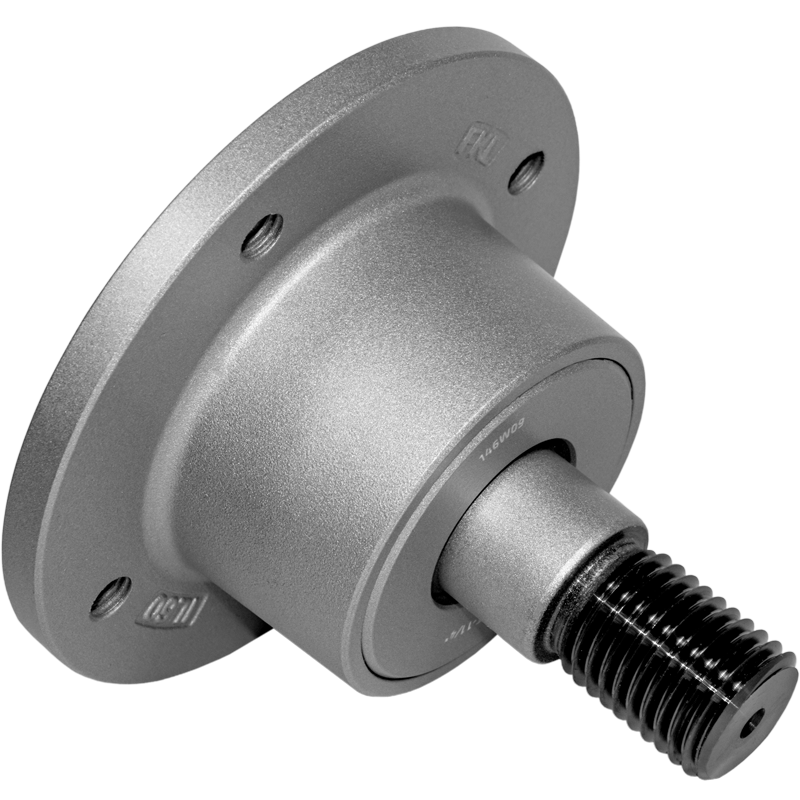

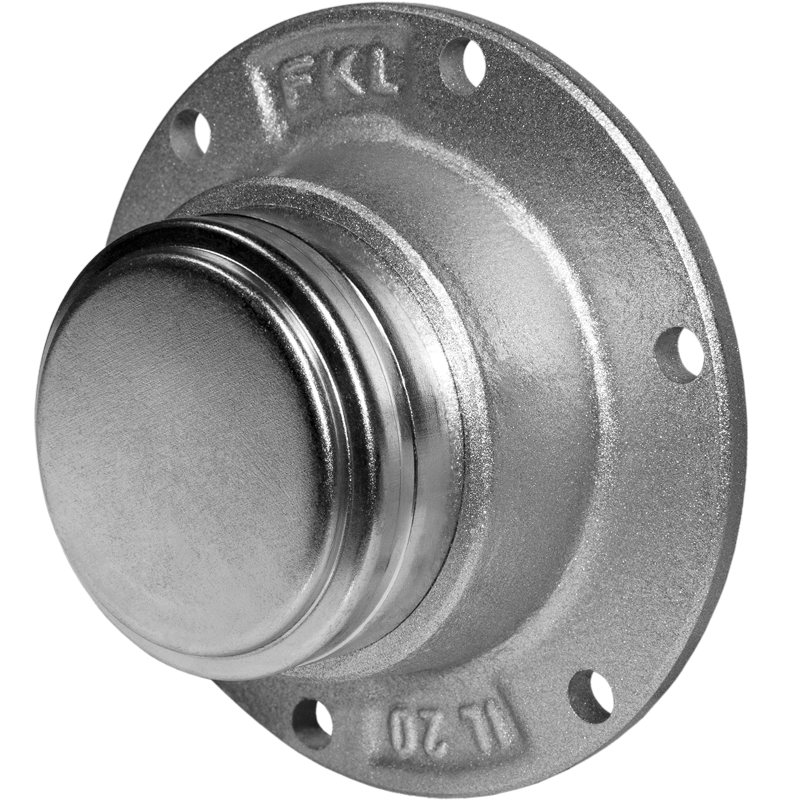

FKL factory is specialized in the production of bearings for application in agricultural machinery. Such bearings are exposed to extreme, often variable radial and axial loads while operating in highly contaminated environments.

Due to such heavy conditions, standard industrial solutions don’t have sufficient service lifetime in agricultural applications. Unlike standard solutions, each FKL bearing is designed for a specific application place, taking into account both the loads and the degree of contamination.

That is why FKL bearings have an extended service lifetime and have shown excellent results in agriculture.

NEWS